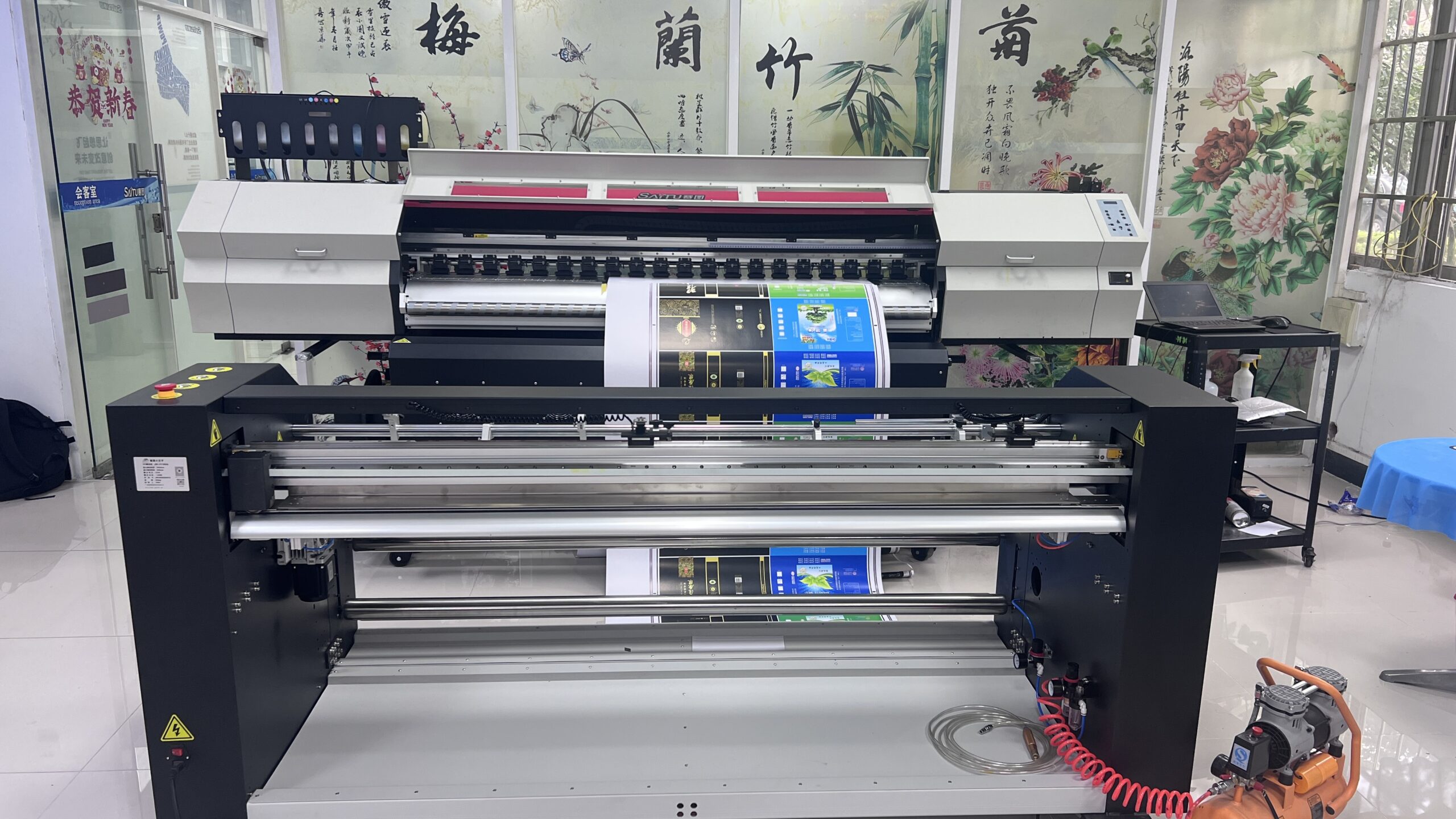

| Model | JC1808 | |

| Maximum print width | 1800mm | |

| Print head | 8 个 Epson i3200-A1 | |

| Speed | 50-55 sqm/h(Material is 1meter size) | |

| Ink | Sort | Pigment ink(8 color:CMYK LC LM LK LLK) |

| Capacity | Empty ink supply system | |

| Material | 1900mm | |

| Material thickness | 1.5mm to 8mm adjustable | |

| Load-bearing capacity | 75KG | |

| Sort | Ivory paper, coated paper | |

| High printing quality | VSD technology | |

| Paper system | Air shaft feeding and take up system | |

| Drying system | Infrared ray drying system | |

| Interface | 1000 Mbit/s | |

| RIP software | Maintop , photo print | |

| Voltage | AC 220V± 10%,50/60 ±1Hz | |

| Operation environments | Temperature: 15℃-30℃,Humidity:35%RH-65%RH | |

| Printer power | 2500W | |

| Power | 9000W | |

| Size of printer (LWH) | 3375*1250*1670mm(1000m) | |

| Size of packing (LWH) | 3640*1135*1590mm | |

| Net weight | 450KG | |

| Gross weight | 550KG | |

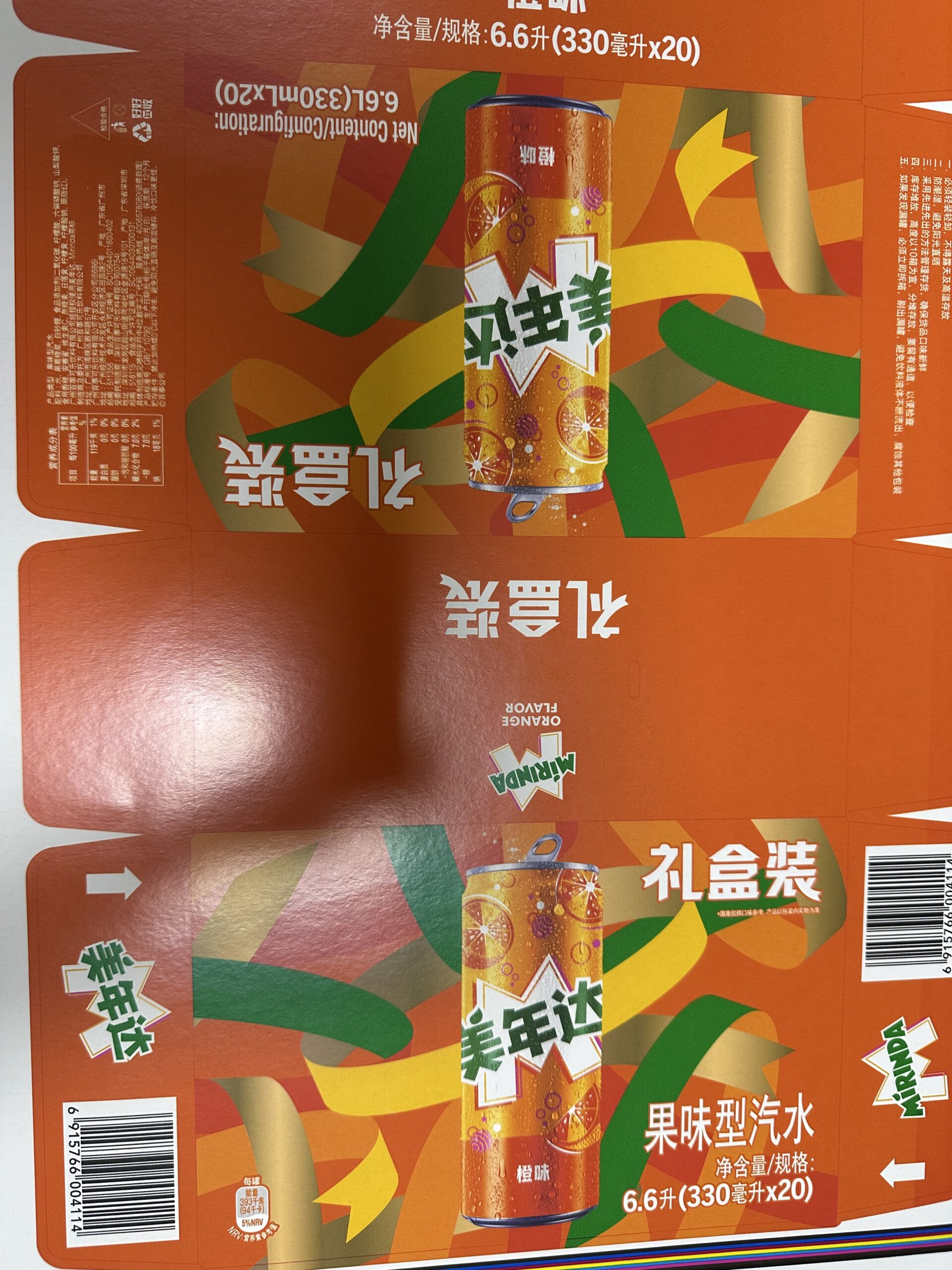

Problems meet: High plate-making costs, and small-batch orders are “unaffordable”

Traditional printing requires the pre-production of printing plates. The cost of plate materials (ranging from several hundred to over a thousand yuan) plus the plate-making time (1-3 days) leads to the plate-making cost for small-batch orders (such as less than 100 copies) being allocated to each product, causing a sharp increase in cost (for example, for a 100-copy order, the plate-making cost is 1,000 yuan, and the cost per copy is 10 yuan, far exceeding the cost of printing itself).

SAITU solution: Plate-free digital printing, directly skipping the plate-making process. Small-batch orders (even one copy) can be produced at low cost, perfectly meeting demands such as “personalized customization” and “trial sales sampling”.

The corresponding advantages and solutions to the pain points of traditional printing by SAITU

The cost of plate-making is high, and small-batch orders cannot afford to lose money. The cost of small-batch orders in plate-free digital printing can be reduced by 50% to 80%.