There are many types of flags, and their uses vary. The rise of the flag manufacturing industry in our country began in the early 1980s. Although it has been seen for over 30 years and has some foundation, the equipment is very simple. Apart from the expired ones, there are very few other types of flags.

There are many types of flags, and their uses vary. The rise of the flag manufacturing industry in our country began in the early 1980s. Although it has been seen for over 30 years and has some foundation, the equipment is very simple. Apart from the expired ones, there are very few other types of flags.

First of all, there is the fabric of the flag. It is rare to make flags with pure cotton fabric. Previously popular varieties such as Shifuchun fabric, straight filament electric fabric, Nisi fabric, and Chunya fabric were not designed for making flags. When needed, they can all be purchased in the market, which is relatively convenient. However, it may not meet the material requirements of the flag. The polyester Fuli textile developed in the 1990s is made of 100D low-elastic polyester filament twisted and woven. Although there are many advantages to using the above fabric, there are many troubles in applying the disperse dye anti-discharge process technology. The permeability, uniformity and vividness of large-area printing are far behind the international level.

Secondly, one of the quality characteristics of the flag is that the color is consistent on both the front and back. Therefore, when choosing the printing process, two requirements should be considered: direct printing must have strong permeability; B. Anti-discharge dyeing process. All the flags in our country are produced by the discharge dyeing process. However, among the flags and various types of flags of over 190 countries around the world, both discharge dyeing and direct printing are adopted. This poses a challenge in terms of craftsmanship, and most flag-making enterprises do not meet the conditions. Therefore, the use of paint to print flags is widespread.

The coating process has its advantages. It is not affected by the properties of the fabric, is easy to operate and can be used for covering The printing coating can produce a discharge effect on a deep background color. However, the shortcomings of the coating process are increasingly exposed. Firstly, the coating process has poor permeability and no double-sided effect. Secondly, it feels hard, which affects the fluidity of the flag. At the same time, the coating color has a certain adsorption property and is highly prone to staining by dust in the air. Moreover, its color fastness is also poor. Therefore, to enhance the quality of both the interior and exterior of flags, it is necessary to employ dyeing techniques, which is the weakest link in China’s flag industry.

Secondly, since the early 1990s, polyester silk disperse dyes have been used in the production of flags. The pure polyester dispersion process is a very normal process in the printing and dyeing industry, and even the polyester discharge dyeing process is relatively mature. However, they are still rare in the flag industry, and it is difficult to coordinate various links. One is the fabric base fabric; The second is dyeing; The third is high-temperature evaporation.

Among them, the main equipment is the steaming machine. To achieve a high temperature of 175-180 degrees, only a continuous steaming machine can be used, but the investment is large. The temperature of the circular high-temperature and high-pressure steamer can only reach 135 degrees. Full drawing is not feasible. Semi-drawing tie-dyeing is the key. Although the semi-drawing process has been used for production for several years, the qualification rate of the flags is still very low and remains in a maintenance state. The direct printing process of disperse dyes also involves post-treatment equipment such as water washing and stretching, which are basically not equipped by existing enterprises.

The imitation wool flags still lack post-treatment, which makes the flags feel hairy and their appearance performance not strong. Overall, polyester flags are gradually expanding, but the process technology still needs to be improved and matched. For nylon fabric flags, except for some national flags, the coating process is not very suitable for them, and the application effect is not good.

In recent years, although there have been special coating printing pastes for nylon (both water-soluble and oil-based types), few have been used for flags. As for printing with acid dyes, the number is even smaller. This is because there are still many operational technical issues in nylon silk screen printing, and the post-treatment is not well-matched, mainly due to the constraints of equipment. Advantages of the thermal sublimation flag machine

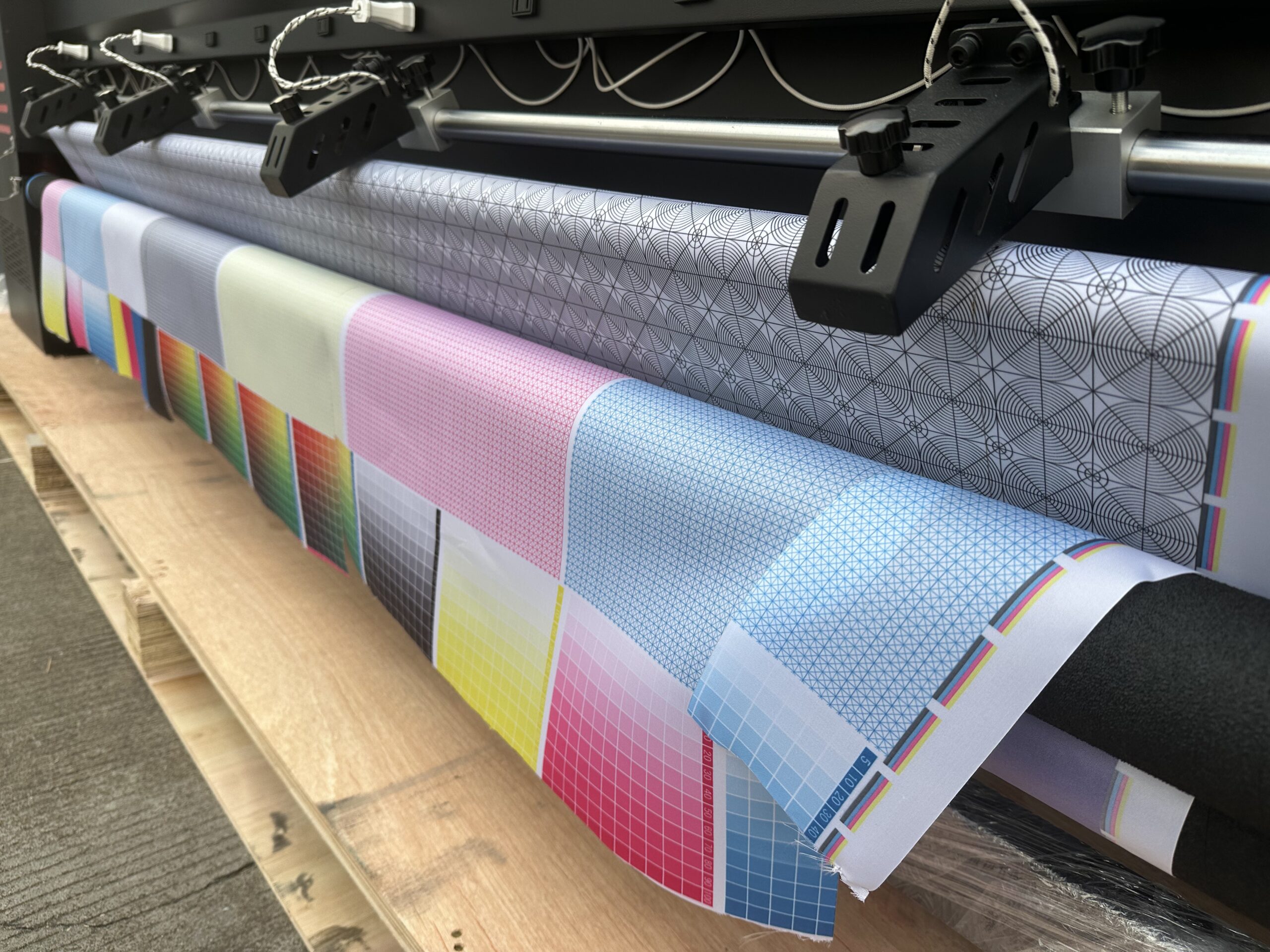

1. Selectable width: The printing width can reach 1.6/2.2/3.1 meters;

2. High-precision printing: Imported original Epson print head, printing speed increased by more than 20%;

3. Heavy-duty structure: When the machine operates continuously, the mechanical parts are more stable.

4. High cost performance, capable of making various digital prints on flag fabrics, etc., with wide applications and high profits.

5. It can directly print on various materials such as double transparent flag cloth, with sublimation ink printing, and does not fade outdoors.